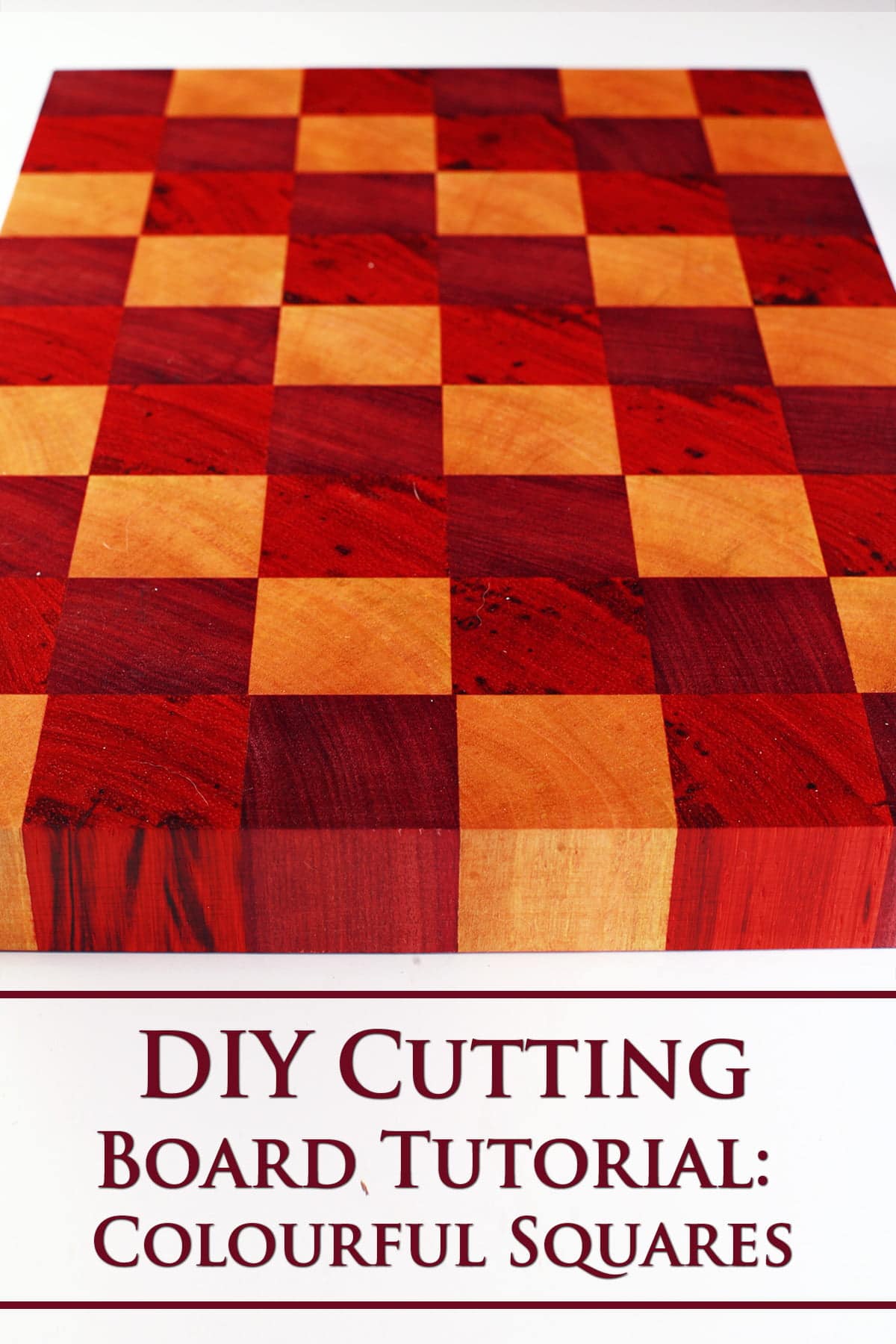

Fancy boards - Cutting, charcuterie, cheese - make great gifts! Here's how to make a DIY Cutting Board - "Colourful Squares" Style!

A little while ago, I posted our first DIY cutting board tutorial: Homemade Cutting Board Tutorial - Log Cabin. Now, it's time for the second one!

I've been having a lot of fun designing and making cutting boards with my husband.

Sure, my part of the whole DIY Cutting Board process is basically choose the wood, design the board, and do the oiling - the vast majority of the work is his.

Whatever!

As a kitchen enthusiast, I am 100% behind the idea of making custom cutting boards as holiday gifts. Cutting, charcuturie, cheese boards - there are all kinds of ways that you can go with this!

For a bit more information on designing your boards, check out my Homemade Cutting Boards 101 post. It has a lot of detail on things like selecting wood and designing for the use (heavy use, vs cheese board, etc).

Our Colourful Squares Cutting Board, before and after oiling it.

Designing Your Colourful Squares DIY Cutting Board

The path to this cutting board was a bit more winding than you’d assume for such a basic pattern. The original idea was to go with a full out 8 bit, old school video game design.

I hadn’t fully narrowed down the possibilities, but I was leaning towards either Super Mario or Space Invaders.

As we’d shown way back when we made our Pi Tile Backsplash , designing with squares can be a lot of fun when you stop thinking of them as tiles, and start thinking of them as PIXELS.

You’re only limited by two things:

1. Your tolerance for fussy work - the smaller the pieces, the more work it is, but the more “resolution” you get - ie, the more complicated your DIY cutting board design can be.

2. Your access to different colours of wood that’s suitable for the type of board you’re making.

Personally, I’d recommend aiming for cheese boards or charcuterie boards if getting REALLY wild with it.. Because it would be *painful* to cut across a really complicated, pixelated cutting board. So much work, I wouldn’t want to ruin it!

So, while this board ended up being a fairly basic repetition of a 3 colour layout, the technique can be used to create any design you can think of. Here’s how:

1. Design Your Cutting Board.

I like to use graph paper for this. Colour in squares as your pixels, with each colour representing a type of wood - it’s a good idea to have a colour key for this, unless you’re being super obvious with your colour usage.

Once you have your design, figure out how big each square will need to be in reality. If you have a design that’s 40 pixels across, you’re not likely to want each square to represent a 1" block of wood, for instance.

Well, unless you’re planning for an EPIC charcuterie board specifically for parties, anyway.

2. Count it Out

Much like with our Pi Backsplash, you’ll want to count out each instance of colour in the blocks, and make a list of them.

I recommend padding your numbers a bit, to allow for any mistakes that may happen.

3. Proceed with the DIY Cutting Board Tutorial

You likely won’t be making use of any sub assemblies, so skip that part... but everything else is good to go.

The big important step involved with making a pixelated design is when you lay it out - we did this in a cookie sheet.

Just make sure to follow your original design as a pattern, and be really careful when gluing your strips, keeping everything in order.

Whichever way you go with the design, just have some fun with it, and be sure to share pics!

Also: Consider using your leftover squares to make a smaller board - like a cheese board. We had a few blocks left over, so we cut them in half - height wise - and made a matching cheese board!

Looking for More Homemade Gift Ideas?

We have a few DIY gift tutorials, with even more coming! For now, be sure to check out:

Booze Bouquet Tutorial.

DIY Citrus and Cedar Bath Set

DIY Mustard Bath Gift Set

Homemade Cutting Board Tutorial - Log Cabin

Homemade Hop Spa Bath Set

Homemade Peppermint Eucalyptus Spa Set

How to Sew A Cute Makeup / Toiletry Bag Travel Set

Mop Doll Air Freshener Covers

DIY Ugly Christmas Sweater Masks

Share the Love!

Before you give away your board, be sure to take some pics of your handiwork! If you post it to Bluesky, be sure to tag us - @CelebrationGen. We're also on Pinterest, so you can save all your favourite recipes to a board!

Also, be sure to subscribe to my free monthly email newsletter, so you never miss out on any of my nonsense.

Well, the published nonsense, anyway!

Anyway, on to that tutorial!

Note: This site is a participant in the Amazon Associates Program, an affiliate advertising program designed to provide a means for the site to earn fees by linking to Amazon and affiliated sites. While I’ll only ever link to items that I, personally, wholeheartedly recommend, I do need to put that disclosure out there!

DIY Cutting Board Tutorial - Colourful Squares

Equipment Needed

Table Saw

Planer

Sander

Chisels

Clamps

Materials Needed

Wood - Your needs will depend on your design.

1 bottle Titebond III Or another Type 3 Glue

Glue brushes

Carpenter Pencils

3 pieces Sandpaper 80, 120, and 180 grit are recommended

1 tube 5-minute epoxy If repairs are necessary

Craft or Popsicle Sticks

Disposable Mixing Containers

Butcher Block Oil or Food Grade Mineral Oil

Confirm Your Design

1. Once you have your design and wood in hand, it’s always good to do a quick confirmation before cutting anything.

2. Measure the widths and lengths required in your design for each wood, and measure what you have on hand. Make sure to include the kerf width for the cuts, as well as allowance for sanding. We use a thin kerf table saw blade, 0.094"(2.4mm) wide, but we use 0.125"(3.2mm) for total allowance, which is a generous allowance to ensure to issues.

Cutting and Planing

1. Rip the pieces to rough squares, if necessary. Make sure to leave extra material for planing.

2. Plane the boards to be the same dimensions. In our design we used a square profile, but equal height rectangles are a perfectly acceptable and normal design.

Six boards are seen on end, all boards have the same dimensions.

3. It is generally a good idea to prepare some scrap pieces of wood - we use pine furring strips or studs - which will aid in clamping. Not only does this prevent the clamps from digging into the workpiece, it helps to displace the clamping force across the surface, providing even clamping force for optimal adhesion. We chose to skip this for some steps where the gluing surfaces were small.

Five boards are clamped together in metal pipe clamps. The outer two boards, which are against the clamps, are cheap pine. The inner three are the high quality boards used in the cutting board.

4. Note: before sanding or planing, clean your station very well. After sanding, scoop up the dust into a ziplock baggie and label it with the type of wood. This dust or chips will come in handy if you need to do repairs.

You can create more later using scrap pieces, if needed, but it’s easier to collect it at this point. It is best to keep wood types/colours separate, but blends can be useful as well.

A ziplock baggie of wood chips is next to two pieces of wood.

Glue Up Subassemblies If Possible

1. In our design, we have a repeating pattern using three colors. By gluing together three of the six pieces before cutting them into blocks, it made subsequent steps a little easier. This is completely optional. This subassembly is seen above in the section discussing using scrap wood to prevent clamp damage. Make sure grain orientation or other features are in the direction of your design.

2. Set up the clamps and assemble everything before gluing. This is important so you’re not fiddling around trying to get the clamp to the right spot when you’ve got glue on your parts and you struggle to manage everything. Leave a little extra room in your clamps so you can slip the pieces in an out easily.

Gluing the Boards

1. It’s easy to put on too much glue, but the key is to have a thin coat of glue on both sides. I like to use the resistance of the brush as a signal. If it’s easy to wipe the glue, it’s too wet and there is too much, I unload the glue from the brush onto a piece of scrap wood. There should be some significant resistance to brushing, it should feel like it’s pulling. Of course, you also want complete coverage, add some more glue if there are blank spots.

Two strips of different colored wood are on the surface of a table. Lines of glue has been applied to the tops of the wood.

The image below illustrates a proper amount of glue after brushing.

Several strips of different colored wood are on the surface of a table. A thin coat of glue has been spread on the top surfaces of the boards.

2. You want to make sure to drive the glue into the grain, all of those tiny little grooves from sanding will be critical to get a good bond. Also make sure to get glue all the way to the edges. If you pieces come apart, they will begin to separate at the edges. If the edges are glued well, the pieces simply can’t separate.

Clamping the boards

1. Set up the glued boards and the clamping boards and lightly clamp them together. Adjust the pieces so the edges line up as perfectly as possible - this will minimize the amount of planing and sanding you’ll do later, as well as minimize waste. Clamp a little tighter to secure, but don’t clamp too hard at this point or the glue will be squeezed out to the sides too much.

Several small strips of multi-colored wood are held together with two clamps from the bottom.

2. It’s important to distribute the clamping force not only along the length, by using multiple clamps, but along the height as well. When we’ve got thin pieces like this, it’s not critical, but it becomes very important later as the workpiece becomes large. If you only clamp from the bottom, for example, the top of the boards won’t be held together properly and you’ll end up with gaps.

Several small strips of multi-colored wood are held together with five clamps.

3. Once you get all of your clamps in place, begin clamping tighter. Alternate around and tighten a little bit at a time. Verify the alignment of your pieces throughout this process - it’s common for the boards to slip a little bit and you don’t want to end up gluing it out of place.

Wait for the glue to dry

1. Waiting is difficult! The pieces will be stuck together fairly well after an hour or so, but planing and sanding may tear them apart. While it’s best to wait overnight between each step, we will continue processing after around three hours, but be very careful since the glue is still fairly weak at this point.

Remove Excess Glue

1. After unclamping the workpiece, you’ll likely see a little excess glue was squeezed out from the joints. A chisel makes quick work of removing this. The planer could easily remove the material, but the little lumps on the bottom side could make the workpiece go through the planer at an angle, skewing the cut. Making the surfaces mostly flat ensures proper planing.

An array of small multi-colored pieces of wood are seen as a flat surface. Glue has bulged out of the seam between two boards. A chisel is on top. The chisel has removed some of the excess glue.

Cut to the correct height

1. Since we're using the end grain as the face of the board, we want to cut all of our wood to the same length. At this point you'll have a lot of small pieces, and possibly some strips if you chose to use subassemblies.

Several strips of wood are seen, each made from three different colors of wood. All of the strips are the same height. The cuts are somewhat rough, from a table saw.

Re-confirm Your Design

1. It's important to lay everything out to make sure it's going to end up exactly how you want it. In our case, we set the grain directions to be consistent across every cube.

54 cubes are laid out in a grid on a cookie sheet

Glue up the strips in one direction

1. It might be tempting to try to be more efficient and glue/clamp in two directions. I highly recommend that you do not try this.

2. It’s difficult enough to ensure everything is aligned and properly clamped in one direction, attempting this in two directions simply has too much risk of error. The way to do this properly is to have a clamping jig that is specifically designed to aid in this type of clamping. Unless you plan on making these as a full time job, it’s simply not worth the effort.

In our design, we could have glued the strips in either direction, we chose to first glue the shorter direction since it makes clamping a little easier. Here we didn't use scrap wood, the clamp face takes up most of the cubes' surface area already.

Maintain the same order and orientation from your layout

Nine sets of wooden cubes are seen on a table, clamped together in metal pipe clamps. Small amounts of glue are seen at some of the joints.

Number the strips as you unclamp them

1. Once you take these to the sander or planer, it's very easy to get them mixed up. Simply number the ends of the strips as you remove them from the clamps. I like to underline the number to ensure I don't get any upside-down.

Plane or Sand

1. Since I have a large drum sander, I chose to do this on my sander. You could easily use a planer to prepare the edges. You want perfectly flat surfaces, but a rough surface (such as what you get with 80 grit sandpaper) is best since you'll be gluing these edges.

Don't bother to plane or sand the ends or faces, which will be the faces of the board. You'll take care of this once it's all glued together.

Repeat!

1. At this point, glue and clamp the strips in the other direction. Here it's a good idea to use scrap wood on the ends while clamping.

An array of small cubes of wood are clamped together into a large rectangle.

Repair Any Gaps

Even if you’re careful, mistakes can happen. If you end up with a gap somewhere in your piece, here's a good method to repair it. This example is from a different project, but the concepts are the same.

A rectangular block made from several pieces of different colored wood is on a table. A gap between two boards is clearly seen.

Or, you may find that your wood has little wormholes or other blemishes.

A light-colored board is on a table saw surface, with small holes in the wood. A sandwich bag with sawdust is on the board.

No worries, we can deal with this! Mixing sawdust - of the type of wood being patched - along with glue or epoxy, will result in a repair that blends in well. We prefer to use epoxy, but many woodworkers use wood glue for repairs.

Prep the tools needed for repair

5-minute epoxy, or wood glue

Craft/popsicle stick

Mixing container (we use disposable shot glasses from the dollar store)

Sawdust of the wood you’re repairing

Heat gun (a hair dryer will work)

A razor blade and/or dental pick can be handy to scrape or move the patch into the seam

Have plenty of sawdust available

It’s hard to know exactly how much sawdust you’ll need, so make sure you have plenty.

For our Padouk example, we cleaned the table well then sanded a scrap piece with the palm sander with a course pad (80 grit).

The palm sander will blow away a fair amount of the dust, so periodically you want to pause to scoop up the sand you’ve created. The groove in the table make convenient areas to scoop the dust for collection.

Prep the repair area

If you’re patching wormholes or other natural defects, use the dental pick to scratch up the surface. This will remove any soft material that is barely holding on, and will create small scratches for better adhesion.

Mix & Fill

1. If you’re using 2-part epoxy, first mix a small amount before adding any sawdust. This will ensure that the epoxy will cure properly.

2. Add sawdust, a little bit at a time until it’s a thick mix. The idea here is that the epoxy or glue is coating the sawdust and holding it all together, which means it’s mostly sawdust.

3. Smear the repair media over the gaps/holes and drive it into the workpiece as much as possible. Make sure there’s extra, both glue and epoxy (to a lesser extent) will shrink a small amount as it cures.

Fill In the Gaps

1. You want to rive the repair media into the workpiece as much as possible. Using the heat gun, gently warm up the repair media. You’ll notice it soften and flow easier. That’s when you should remove the heat. Too much heat will cause epoxy to cure prematurely, and will cause glue to dry out.

2. Now that the media is soft, you can use your tools to drive it even deeper into the workpiece. Add more repair media on top, if needed.

3. For our gap, we used the craft stick to wedge the repair media as deep as possible.

4. The repair looks dark, compared to the Padouk piece. The Padouk will get darker when the finishing oil is applied, and the repair will blend better.

Wait and Scrape

Just like every glue step, wait for the adhesive to cure, scrape off the excess with a chisel.

Final planing and sanding!

1. Now it is really looking like a cutting board! Perform the final planing and sanding. Lightly sanding the edges at a 45 degree angle will break the sharp edges. Do this manually, any power tool will remove edge material too quickly.

Again I chose to do all of this final work on the drum sander, skipping the planer. Although this was time-consuming, it prevented any potential issues with tearout or snipe. On a planer, make sure to remove very thin slices on each pass, and use care when feeding your piece into the machine, to reduce the chance of these issues.

The cutting board, made from an array of small cubes, is seen face up. The surface is smooth but slightly hazy from the rough sanding.

2. For the edges of the cutting board, a joiner is a great way to finish the edge. If you don't have one, a hand planer can remove large bumps and a sander can take care of the rest.

Make sure to keep the sander flat on the edge, and don't press too hard. Pressing hard to holding the sander at an angle will round off the edge of the board slightly.

3. We like to finish off with a finer grit, 180. We used the palm sander for this final step, to prevent directional sanding marks left by the drum sander. This eliminates the visible scratches but leaves the wood grains somewhat open, allowing the finish to penetrate. The surface appears slightly shiny at this point.

The cutting board, made from an array of small cubes, is seen face up. The surface is smooth and slightly shiny from the fine sanding.

Finishing

1. Pour a bit of the Bio-Supra* on the surface of your cutting board, and use a small plastic scraper / squeegee to spread it around.

The cutting board is seen on a table. A small amount of white fluid is on top of the cutting board. A squeegee is next to the cutting board on the table.

2. Use a foam craft brush to apply the oil to the sides and ends of the board, in a THIN coat.

3. Wait 5 minutes

4. Using a clean, lint-free piece of cotton - a rag or an old shirt - wipe off excess oil. Continue wiping until there is no more finish coming off onto the rag as you wipe it.**

5. Let it dry for 24 hours.

6. Use a grey buffing pad to lightly abrade the surface of your project.

7. Pour a very small amount of oil onto the surface of the cutting board - less than you needed for the first round, as this round will go further.

8. Use a small piece of white puffing pad to work the oil into the first coat.

9. Once more, use a clean, lint-free piece of cotton - a rag or an old shirt - wipe off excess oil. Continue wiping until there is no more finish coming off onto the rag as you wipe it.**

Notes

* If you are using a different finishing oil, follow the manufacturer’s directions for it.

** Carefully dispose of your oil soaked rags, as they are HIGHLY flammable. You can either lay them out on concrete - or hang them up in the outside air - until they are completely dry, or soak them overnight in water.

After drying or soaking, you can dispose of them in your regular garbage.

Homemade Cutting Board - Colourful Squares Style

Equipment

- Table Saw

- Planer

- Sander

- Chisels

- Clamps

Ingredients

- 6 pieces Wood Your design may vary!

- 1 bottle Titebond III Or another Type 3 Glue

- 6 pieces Glue brushes

- Carpenter Pencils

- 3 pieces Sandpaper 80, 120, and 180 grit are recommended

- 1 tube 5-minute epoxy If repairs are needed

- Craft or Popsicle Sticks

- Disposable Mixing Containers

Instructions

Confirm your design

- Once you have your design and wood in hand, it’s always good to do a quick confirmation before cutting anything.

- Measure the widths and lengths required in your design for each wood, and measure what you have on hand. Make sure to include the kerf width for the cuts, as well as allowance for sanding. We use a thin kerf table saw blade, 0.094"(2.4mm) wide, but we use 0.125"(3.2mm) for total allowance, which is a generous allowance to ensure to issues.

Cutting and planing the boards

- Rip the pieces to rough squares, if necessary. Make sure to leave extra material for planing.

- Plane the boards to be the same dimensions. In our design we used a square profile, but equal height rectangles are a perfectly acceptable and normal design.

- It is generally a good idea to prepare some scrap pieces of wood - we use pine furring strips or studs - which will aid in clamping. Not only does this prevent the clamps from digging into the workpiece, it helps to displace the clamping force across the surface, providing even clamping force for optimal adhesion. We chose to skip this for some steps where the gluing surfaces were small.

- Note: before sanding or planing, clean your station very well. After sanding, scoop up the dust into a ziplock baggie and label it with the type of wood. This dust or chips will come in handy if you need to do repairs. You can create more later using scrap pieces, if needed, but it’s easier to collect it at this point. It is best to keep wood types/colours separate, but blends can be useful as well.

Glue up subassemblies if it will help

- In our design, we have a repeating pattern using three colors. By gluing together three of the six pieces before cutting them into blocks, it made subsequent steps a little easier. This is completely optional. This subassembly is seen above in the section discussing using scrap wood to prevent clamp damage. Make sure grain orientation or other features are in the direction of your design.

- Set up the clamps and assemble everything before gluing. This is important so you’re not fiddling around trying to get the clamp to the right spot when you’ve got glue on your parts and you struggle to manage everything. Leave a little extra room in your clamps so you can slip the pieces in an out easily.

Gluing the boards

- It’s easy to put on too much glue, but the key is to have a thin coat of glue on both sides. I like to use the resistance of the brush as a signal. If it’s easy to wipe the glue, it’s too wet and there is too much, I unload the glue from the brush onto a piece of scrap wood. There should be some significant resistance to brushing, it should feel like it’s pulling. Of course, you also want complete coverage, add some more glue if there are blank spots.

- The image below illustrates a proper amount of glue after brushing.

- You want to make sure to drive the glue into the grain, all of those tiny little grooves from sanding will be critical to get a good bond. Also make sure to get glue all the way to the edges. If you pieces come apart, they will begin to separate at the edges. If the edges are glued well, the pieces simply can’t separate.

Clamping the boards

- Set up the glued boards and the clamping boards and lightly clamp them together. Adjust the pieces so the edges line up as perfectly as possible - this will minimize the amount of planing and sanding you’ll do later, as well as minimize waste. Clamp a little tighter to secure, but don’t clamp too hard at this point or the glue will be squeezed out to the sides too much.

- It’s important to distribute the clamping force not only along the length, by using multiple clamps, but along the height as well. When we’ve got thin pieces like this, it’s not critical, but it becomes very important later as the workpiece becomes large. If you only clamp from the bottom, for example, the top of the boards won’t be held together properly and you’ll end up with gaps.

- Once you get all of your clamps in place, begin clamping tighter. Alternate around and tighten a little bit at a time. Verify the alignment of your pieces throughout this process - it’s common for the boards to slip a little bit and you don’t want to end up gluing it out of place.

Wait for the glue to dry

- Waiting is difficult! The pieces will be stuck together fairly well after an hour or so, but planing and sanding may tear them apart. While it’s best to wait overnight between each step, we will continue processing after around three hours, but be very careful since the glue is still fairly weak at this point.

Remove excess glue

- After unclamping the workpiece, you’ll likely see a little excess glue was squeezed out from the joints. A chisel makes quick work of removing this. The planer could easily remove the material, but the little lumps on the bottom side could make the workpiece go through the planer at an angle, skewing the cut. Making the surfaces mostly flat ensures proper planing.

Cut to the correct height

- Since we're using the end grain as the face of the board, we want to cut all of our wood to the same length. At this point you'll have a lot of small pieces, and possibly some strips if you chose to use subassemblies.

Confirm your design

- It's important to lay everything out to make sure it's going to end up exactly how you want it. In our case, we set the grain directions to be consistent across every cube.

Glue up the strips in one direction.

- It might be tempting to try to be more efficient and glue/clamp in two directions. I highly recommend that you do not try this. It’s difficult enough to ensure everything is aligned and properly clamped in one direction, attempting this in two directions simply has too much risk of error. The way to do this properly is to have a clamping jig that is specifically designed to aid in this type of clamping. Unless you plan on making these as a full time job, it’s simply not worth the effort.

- In our design, we could have glued the strips in either direction, we chose to first glue the shorter direction since it makes clamping a little easier. Here we didn't use scrap wood, the clamp face takes up most of the cubes' surface area already.Maintain the same order and orientation from your layout

Number the strips as you unclamp them

- Once you take these to the sander or planer, it's very easy to get them mixed up. Simply number the ends of the strips as you remove them from the clamps. I like to underline the number to ensure I don't get any upside-down.

Plane or sand the ends of the strips

- Since I have a large drum sander, I chose to do this on my sander. You could easily use a planer to prepare the edges. You want perfectly flat surfaces, but a rough surface (such as what you get with 80 grit sandpaper) is best since you'll be gluing these edges.Don't bother to plane or sand the ends or faces, which will be the faces of the board. You'll take care of this once it's all glued together.

Repeat!

- At this point, glue and clamp the strips in the other direction. Here it's a good idea to use scrap wood on the ends while clamping.

Oops.

- Even if you’re careful, mistakes can happen. If you end up with a gap somewhere in your piece, here's a good method to repair it. This example is from a different project, but the concepts are the same.

- Or, you may find that your wood has little wormholes or other blemishes.

- No worries, we can deal with this! Mixing sawdust - of the type of wood being patched - along with glue or epoxy, will result in a repair that blends in well. We prefer to use epoxy, but many woodworkers use wood glue for repairs.

Prep the tools needed for repair

- 5-minute epoxy, or wood glue

- Craft/popsicle stick

- Mixing container (we use disposable shot glasses from the dollar store)

- Sawdust of the wood you’re repairing

- Heat gun (a hair dryer will work)

- A razor blade and/or dental pick can be handy to scrape or move the patch into the seam

Have plenty of sawdust available

- It’s hard to know exactly how much sawdust you’ll need, so make sure you have plenty.

- For our Padouk example, we cleaned the table well then sanded a scrap piece with the palm sander with a course pad (80 grit).

- The palm sander will blow away a fair amount of the dust, so periodically you want to pause to scoop up the sand you’ve created. The groove in the table make convenient areas to scoop the dust for collection.

Prep the repair area

- If you’re patching wormholes or other natural defects, use the dental pick to scratch up the surface. This will remove any soft material that is barely holding on, and will create small scratches for better adhesion.

Mix the repair media and fill the piece

- If you’re using 2-part epoxy, first mix a small amount before adding any sawdust. This will ensure that the epoxy will cure properly.

- Add sawdust, a little bit at a time until it’s a thick mix. The idea here is that the epoxy or glue is coating the sawdust and holding it all together, which means it’s mostly sawdust.

- Smear the repair media over the gaps/holes and drive it into the workpiece as much as possible. Make sure there’s extra, both glue and epoxy (to a lesser extent) will shrink a small amount as it cures.

Drive the repair media into the workpiece as much as possible

- Using the heat gun, gently warm up the repair media. You’ll notice it soften and flow easier. That’s when you should remove the heat. Too much heat will cause epoxy to cure prematurely, and will cause glue to dry out.

- Now that the media is soft, you can use your tools to drive it even deeper into the workpiece. Add more repair media on top, if needed.

- For our gap, we used the craft stick to wedge the repair media as deep as possible.

- The repair looks dark, compared to the Padouk piece. The Padouk will get darker when the finishing oil is applied, and the repair will blend better.

Wait and scrape.

- Just like every glue step, wait for the adhesive to cure, scrape off the excess with a chisel.

Final planing and sanding!

- Now it is really looking like a cutting board! Perform the final planing and sanding. Lightly sanding the edges at a 45 degree angle will break the sharp edges. Do this manually, any power tool will remove edge material too quickly.Again I chose to do all of this final work on the drum sander, skipping the planer. Although this was time-consuming, it prevented any potential issues with tearout or snipe. On a planer, make sure to remove very thin slices on each pass, and use care when feeding your piece into the machine, to reduce the chance of these issues.

- For the edges of the cutting board, a joiner is a great way to finish the edge. If you don't have one, a hand planer can remove large bumps and a sander can take care of the rest.Make sure to keep the sander flat on the edge, and don't press too hard. Pressing hard to holding the sander at an angle will round off the edge of the board slightly.

- We like to finish off with a finer grit, 180. We used the palm sander for this final step, to prevent directional sanding marks left by the drum sander. This eliminates the visible scratches but leaves the wood grains somewhat open, allowing the finish to penetrate. The surface appears slightly shiny at this point.

Finishing

- Pour a bit of the Bio-Supra* on the surface of your cutting board, and use a small plastic scraper / squeegee to spread it around.

- Use a foam craft brush to apply the oil to the sides and ends of the board, in a THIN coat.

- Wait 5 minutes

- Using a clean, lint-free piece of cotton - a rag or an old shirt - wipe off excess oil. Continue wiping until there is no more finish coming off onto the rag as you wipe it.**

- Let it dry for 24 hours.

- Use a grey buffing pad to lightly abrade the surface of your project.

- Pour a very small amount of oil onto the surface of the cutting board - less than you needed for the first round, as this round will go further.

- Use a small piece of white puffing pad to work the oil into the first coat.

- Once more, use a clean, lint-free piece of cotton - a rag or an old shirt - wipe off excess oil. Continue wiping until there is no more finish coming off onto the rag as you wipe it.**

[…] Credit: celebrationgeneration.com […]